Swab independently a variety of parts of the products soon after cleaning and final rinsing of pieces as in-depth from the sampling program.

It also needs to specify the volume of validation operates required to establish the success from the cleaning process. Normal education of operators to the protocol is critical to guarantee steady and exact execution of cleaning validation processes.

Chance-Based mostly Tactic: Utilizing a chance-centered approach can help prioritize cleaning endeavours and assets. Makers must perform a radical danger assessment to discover crucial parts and concentrate on them during the cleaning validation course of action.

The most stringent price from the above 4 standards shall be considered as acceptance requirements for cleaning validation like visual conditions.

Acceptance conditions for cleaning validation protocols considers boundaries for chemical substances and actives, restrictions for bio burden, visually cleanliness of surfaces, and the demonstration of consistency when executing the cleaning process. Concerning the institution of boundaries, FDA will not plan to set acceptance specifications or methods for pinpointing no matter if a cleaning process is validated. Present-day anticipations for location cleaning limitations contain the application of hazard administration rules plus the consideration of Wellbeing Primarily based Exposure Restrictions as The premise for placing cleaning restrictions for actives.[three] Other boundaries that were stated by industry contain analytical detection stages including ten PPM, biological activity levels for instance one/one thousand of the normal therapeutic dose and organoleptic amounts.[4][5][6]

Finish information and facts of all cleaning techniques, procedure parameters, and responsibilities must be adequately recorded. The recording technique need to clearly proof the completion of all cleaning activities and protocol adherence while making certain info integrity. Correct documentation forms the basic principles of cleaning validation in pharmaceutical industry.

Pharmaceutical equipment and machinery are correctly cleaned after a product has long been produced to avoid the contamination of subsequent products which are going to be made. The process of removing of former product or service residues, impurities, and extraneous product from manufacturing instruments is known as cleaning.

At Pritchard, we offer cleaning & disinfecting solutions combined with the option to carry out a verification approach. Right after Just about every cleaning occasion, the validation makes sure equipment meets the correct expectations prior to reuse.

• the acceptance criteria (with rationale for environment the specific boundaries) such as a margin for error and for sampling performance;

Here we talked about handful of popular job interview issues and answers on scientific pharmacist Q. What is usually a scientific pharmacist? A medical pharmacist is really a healthcare provider, who provides immediate patient treatment, here medication…

With an Extractables Evaluation, substances located in the standard extractables analyses underneath affordable worst-situation circumstances might be evaluated for specific customer processes. This offers you an extensive understanding of, and self esteem in, the Sartorius factors utilised within your processes.

Cleaning validation protocols variety an integral part of the process used to keep up product quality & security across different industries. Below are a few situation whenever a cleaning validation procedure could be practical:

The selection in the worst circumstance for cleaning validation is typically according to components which include drug solubility, The issue of kit cleaning, along with the here occupancy of merchandise during the creation line.

Cleaning validation is an important approach in the pharmaceutical industry that assures producing equipment is properly cleaned to prevent solution contamination. Adhering to Present-day Great Production Observe (cGMP) and Quality Programs Polices (QSR), cleaning validation as being a vital part of high-quality assurance performs a vital function in making certain the production course of action continues to be not just economical but in addition compliant with health and safety expectations.

Mr. T Then & Now!

Mr. T Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Andrea Barber Then & Now!

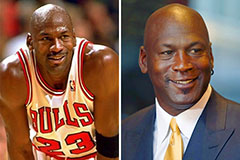

Andrea Barber Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!